No matter how much time, effort, and money you put into promoting your business and converting visitors into buyers, you’ll never create repeat customers if you screw up fulfillment.

This is partly why I hate out-sourced fulfillment and drop-shipping. Once you lose control over this monumental link in the customer lifecycle chain, you’re headed for disaster. So, you MUST become an expert in fulfillment if you’re going to run a successful e-commerce business.

Just think of how silly it would be if brick-and-mortar stores outsourced their in-store workers. Imagine you walk up to the register at BestBuy and the person greeting you is wearing a shirt for “OutsourcedRegisters, Inc”. That’s terrible! And that’s precisely what you’re doing when you outsource your fulfillment operations. You’re leaving your final interaction with the customer — the thing most memorable in their mind — up to someone else. Unless you have a very specific reason for outsourcing your fulfillment, don’t do it.

Instead, let’s examine how you can do it yourself and enjoy near 100% accuracy in your fulfillment. We’ve done it at my company where our rate of mistake (being defined as sending the wrong item to a customer, omitting an item, or sending too much of an item) is well below 0.1%.

A few caveats: We’ve only tested our system up to 2,000 orders in one day. Also, we wrote our own customized software, but I’m sure you could find products out there to achieve similar results. If not, hire someone to write the software for you. It’ll be worth every penny. The program isn’t very complex, so it wouldn’t cost much to have it created for you.

We use a batch picking process. This means that we break up all of our available orders into discreet batches of orders. Our software determines how many physical items are required to fulfill the available orders and then breaks them up so that each batch has, at most, 60 items (not orders) per batch. This ensures that our carts aren’t overloaded.

We then print out the pick list which details how many of each item is required for this batch. The list is sorted by location so that a worker can walk up and down our warehouse aisles and grab all of the items needed for these orders and place them onto their picking cart.

At this point, the cart theoretically contains all of the items required for this batch of orders. When we’re done fulfilling these orders, the cart should be empty. If it isn’t, there’s a problem that must be addressed. This is your first line of defense against errors.

Next, we load the pick list into our scanning software. Our employee can simply scan the barcode printed at the top of the picklist using an inexpensive (about $250) omnidirectional scanner. These are far better than handheld scanners because you don’t have to press a button to activate the scanning. You can simply hold the barcode underneath it (at nearly any orientation) and it’ll scan. It’s wonderful. They have no moving parts and will last a lifetime.

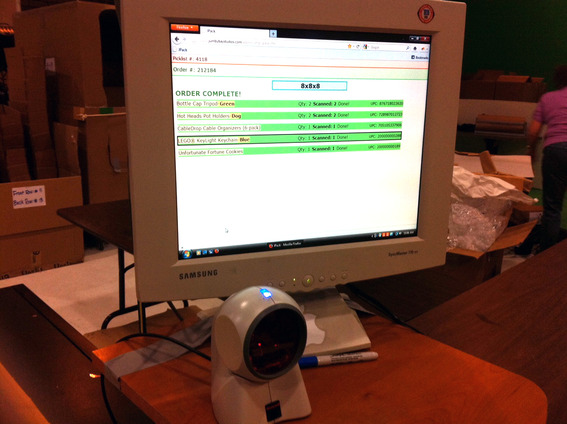

Scanning software

A note on barcodes: If the product you’re selling doesn’t have a UPC, make the manufacturer put one on it. In today’s world, there’s no excuse for not having it. If they refuse, create your own labels. You don’t need to purchase a UPC prefix if you’re just using it for your own warehouse needs. In fact, there’s a free prefix designated for in-house use. You also shouldn’t need to purchase expensive software to print barcodes. The software we use costs about $50. Blank labels are also extremely inexpensive. We buy 12,000 blank peel-and-stick labels for about $30 that we run through a $100 laser printer.

Once the picklist is loaded, the process is simple: the worker scans the barcode on the packing slip for the order and then scans each item before they put it into the box for that order. If there’s a mistake, they receive an annoying beep.

Once the order is properly scanned, the order is marked as complete, and sent to the next person to pack the order. This continues until the batch is complete. If there are any items missing at the end of the batch, the worker can hit a key on their keyboard to bring up a report showing every item that was scanned. This can help them pinpoint where their error occurred.

By working on small batches at one time, you reduce the potential for errors. By strictly enforcing the use of barcodes on every item, you can achieve 99%+ accuracy. Obviously, you must have employees who are properly trained to use the system and who listen to the feedback it provides. If they don’t, well… you find someone else!

I’ve included a screenshot of what our little piece of software looks like that handles the scanning of each order. You’ll also notice our $250 scanner underneath the monitor.

On the screenshot, you’ll see “8x8x8” in a blue box. That tells our worker what size box is required for this order. You can also see a green bar for every item in the order. They’ve been turned green because the items required were scanned. Once all are green, the computer plays a chime sound and the worker is then free to scan a new order. They cannot scan a new order until they finish the order they’re working on.

The point here is that fulfillment isn’t a black art. Jump in, figure it out, and take control over this increasingly important aspect of your e-business. By using a checks-and-balances system like the one I’ve described above, you can feel confident knowing that all of your orders are fulfilled accurately and promptly. Your customers will sincerely appreciate getting exactly what they ordered!