SKU management is the process of analyzing the cost of carrying each inventory item to ensure it is meeting the financial objectives of the business.

If your business is virtual and you sell drop-shipped items — thus providing the ability to sell the product without owning it — this is less of a concern but by no means of no concern. That’s because there are two finite resources in managing your business: time and money. Even if you think the number of SKUs you offer, via drop shipping, is unlimited and costs no money, the truth is that merchants often spend too much time selling low-margin items.

SKU management is therefore critical for drop-shipped items as well as purchased inventory. What is the real cost of offering or holding inventory month after month — I’ve seen years — that isn’t selling?

The benefits of good SKU management include:

- Optimizing inventory levels (right stock at the right time);

- Increased revenue;

- Increased gross margins;

- Increased efficiency.

The risks of poor SKU management include:

- High inventory holding costs;

- Reduced available capital;

- Higher fixed costs;

- Reduced efficiencies.

Setting Up SKU Management

Here’s one approach to SKU management.

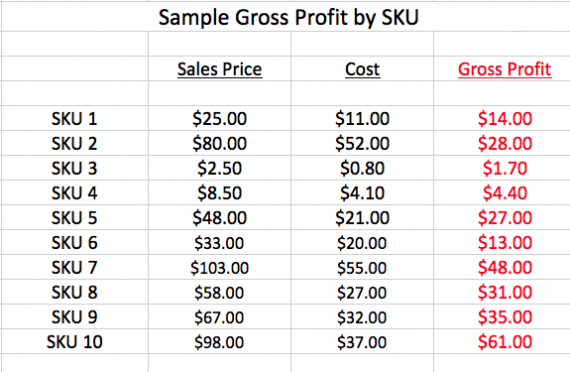

Step 1: Calculate the SKU ratio. In a spreadsheet, create a gross profit range, which lists the selling price, cost, and gross profit by product(s). The selling price, cost, and gross profit would be in columns and the products would be in rows. (Selling price – cost = gross profit.)

A gross profit range lists the selling price, cost, and gross profit by product.

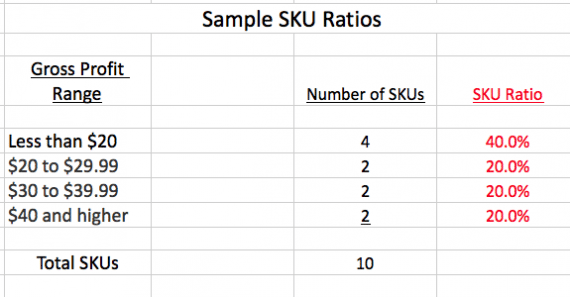

Next create gross profit ranges in a spreadsheet to understand your better performing SKUs. Say your products sell between $10 and $50. Potential gross profit ranges could be as follows.

- Less than $20

- $20 to $29.99

- $30 to $39.99

- $40 and higher

Enter the number of SKUs in each range to determine the SKU ratio. The SKU ratio is determined by the number of SKUs in a gross profit range divided by the total number of SKUs and then multiply by 100 percent.

The SKU ratio is determined by the number of SKUs in a gross profit range divided by the total number of SKUs.

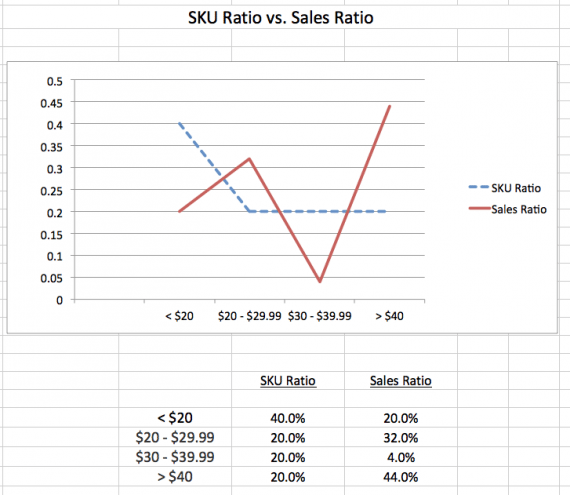

Step 2: Calculate the sales ratio. In the same gross profit range, enter the number of sales units per range. To calculate the sales ratio, divide the number of sales units in a gross profit range by the total number of sales units and then multiply by 100 percent.

Compute the sales ratio, by dividing the number of sales units in a gross profit range by the total number of sales units.

Step 3: Understand the findings. To help understand the findings, plot a line graph for the SKU analysis that shows the SKU ratio versus the sales ratio. This will show the best performing SKU range — where the sales ratio is higher than the SKU ratio by the largest amount. The worst performing SKU range is where the SKU ratio is higher than the sales ratio by the largest amount.

Comparing the SKU ratio to the sales ratio shows the best performing SKU range — where the sales ratio is higher than the SKU ratio by the largest amount.

Now What?

Your best performing SKU range means that there is higher demand for the product(s) and that there is potential for generating greater sales volume if you increase marketing, inventory, or varieties. Your worst performing SKU range means that there is too much supply and that you are using your resources (time and money) poorly. You should reduce marketing, reduce inventory, and or remove the products.

Completing this exercise for the first time can be tedious. Look to automate the process through either an order management program or a software solution that will pull the data automatically. Do the process at least this quarterly — even if it’s manual (not automated) — to ensure that you’re not making critical mistakes with your two most finite resources, time and money.

In my next article, I’ll expand the evaluation of SKU management with the broader question of what the true cost of inventory is. Mastering this part of your business can make a material difference in your company’s profitability.