As the owner of a fulfillment company, I’ve gathered a number of tips and discovered an assortment of traps over the years. If you’re thinking about outsourcing your warehousing, shipping, and returns processing, let me suggest that you follow these guidelines. They will help you find a vendor that can provide the kind of fulfillment service you need at a cost you can afford.

Gather Your Facts And Figures

Before you begin your vendor search you need to assess your shipping and warehousing needs.

What is your monthly order volume? What is your average SKU (stock-keeping unit) per order? What is the average number of items per order, typical package weights, and your “ship via” percentages, which is the number of first class mail vs. priority mail packages or UPS/FedEx ground vs. air packages. These are all questions that need to be answered.

It’s also necessary to know how many inventory SKUs and item counts that will need to be warehoused and an estimate of how many cubic feet of warehouse space will be required. This is often expressed as standard 4′ × 4′ × 4′ pallets of 64 cubic feet each even though your products could be stored on shelves instead of pallets. You will also need the dollar value of your inventory for the warehouse’s insurance coverage.

Lastly, you need to know if your web store shopping cart or accounting system can export your fulfillment data as CSV or XML files and what extra services you may need such as COD processing, international shipping, kitting, or assembly labor.

Formulate Your Request-for-proposals List

Once you have your fulfillment data you can begin your vendor search.

A good starting point is the Yahoo! directory of fulfillment service providers. Each listing includes a concise summary of what kind of fulfillment the vendor offers, such as ecommerce fulfillment, direct mail fulfillment, reverse logistics fulfillment, and so on.

After you visit each selected website, contact the companies you are interested in via email. Ask them for a quotation and proposal based on your unique order fulfillment information.

Compile Results

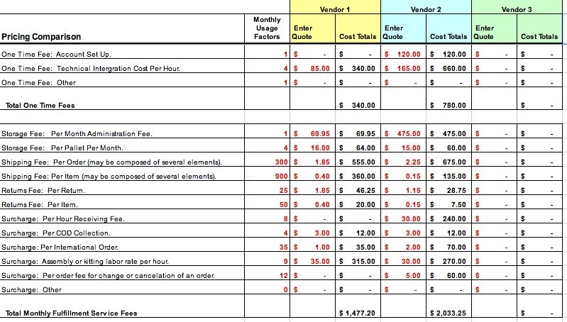

As you receive quotes and proposals, you might want to create a side-by-side comparison spreadsheet like this one:

Screenshot of comparison spreadsheet.

Click here to download a working version of the spreadsheet.

Enter your usage factors into the spreadsheet and then enter the prices and terms provided by each vendor. By comparing the facts and figures, you can quickly move to the next step, which is to interview the sales representatives and perhaps tour the facilities of the top two or three prospects.

Location, Location, Location

Make certain your fulfillment service provider is as near to your customers as possible. This will minimize zone-based shipping charges. A good test is to enter each vendor’s zip code into the UPS online system to create a zone map for each potential shipping location.

Questions to Ask

One of the things to discuss with a potential fulfillment house is what kind of order processing they use and how your project would be handled in their production system.

Most fulfillment houses offer pick-to-order processing, which means the individual items are picked for each order in totes and then packaged and shipped. This is a good solution for projects that average more than four SKUs or items per order, although it has the highest per order labor input.

Batch picking involves gathering all the SKUs and items needed for a group of orders and then packing individual orders from that collection of merchandise. This speeds the picking time and provides a built in error trap between the picking and packing functions. This is normally used for projects that have three or fewer SKUs or items per order.

Bulk processing is used when there is heavy order volume involving fewer than 10 SKUs (as the entire picking, packing and shipping operation can be consolidated to a single work station.) This is an ideal solution for volume sales of books, electronic media, and diet supplements because labor cost is minimized.

At my company, orders are divided among a pick-to-order production cell, a batch picking cell, and a bulk process cell.

10 Tips and Traps

As you decide on a fulfillment partner, my experience suggests that you consider these ten points.

-

Analyze the contract. You can quickly compare each proposed fulfillment contract with an industry model contract provided by the Mailing & Fulfillment Service Association.

-

Watch storage fees. Be careful about per-pallet storage (warehousing) quotes as some companies have a one SKU per pallet minimum. This would mean a minimum charge per month for each of your SKUs no matter how few items might be on hand. If you have a growing SKU list, the cost could spin out of control.

-

Consider the size. An area that may seem trivial, but isn’t, is the range of stock carton and Jiffy mailer sizes provided by the fulfillment house. Use of oversize cartons or envelope mailers can trigger a huge increase in the postage, UPS and FedEx charges because of the unnecessary package weight involved. See my previous article on avoiding dimensional weight problems, “Shipping: Dimensional Weight Errors Can Cost Big Bucks”.

-

Avoid split orders. Splitting orders into two or more small boxes because larger cartons are not available is also be a problem. Your fulfillment house should be willing to use special cartons that you provide if its largest stock carton isn’t big enough.

-

Get specialized cartons. Consider that you may need a special-size carton to avoid DIM surcharges. Even a fraction of an inch in one dimension can make a big difference in your monthly shipping expense if you ship low density products in large cartons.

-

Options for Returned Merchandise. Make certain your fulfillment house gives you the option to either have your customers ship returned merchandise back to you directly or to them for processing. In the case of most food and diet supplements, for example, it is cheaper to have returned merchandise sent directly to you because re-sale is not feasible.

-

Consider the shipping account. Some fulfillment houses use your shipping account and others use their own UPS, FedEx and postal accounts. (You will notice typical rates and fees are adjusted to reflect this.) In many cases you will be better off to shut down your own shipping accounts because of the combined buying power and resulting discounts provided by the fulfillment house.

-

Check the terms of service. Established fulfillment houses guarantee their work and will compensate you for errors that they make but it is a good idea to check the written terms of service for each potential vendor to make sure there is no misunderstanding.

-

Digital photography services. Ask if the potential fulfillment vendor provides on-site digital photography services. This will be helpful if you frequently have new SKUs drop-shipped directly from your supplier to your fulfillment house. This is especially true for eBay power sellers who outsource their order fulfillment.

-

Accommodate gift wrapping. Remember that few fulfillment companies provide gift wrapping services. One way around this is to pre-wrap and package for shipment selected merchandise and provide these as stand alone SKUs in the fulfillment center’s inventory system. When you receive an order for gift wrapped merchandise you can then substitute the gift wrapped version for routine SKU number.

Summing Up

Fulfillment outsourcing is a logical, step-by-step process. You start by gathering the facts and figures about your present and planned order fulfillment needs. You acquire a set of quotations and proposals from established companies and compare them in an organized way. Then you carefully interview selected prospects and, if possible, visit their facilities.

You can start on a small scale by sending just a few SKUs and small quantities of each item and carefully test the potential fulfillment partner before making a long term commitment. This is an especially good idea if you are automating the fulfillment data-export process from your web store to the fulfillment center’s control panel, as you will be working with the fulfillment house technical staff to resolve the details.