The primary benefit of drop shipping for retailers is the ability to access merchandise without incurring physical inventory carrying costs. It also enables suppliers to open new channels or penetrate existing ones more completely.

If you’re new to drop shipping, read my 4-part series on the basics, as well as my articles about managing product catalog data, inventory visibility, orders, fulfillment, returns, and invoices.

In past articles, I’ve covered various aspects of drop shipping, outlining both the challenges and benefits that arise from replacing inventory with a different cost area: generating, managing, updating, integrating, and sharing data.

Dealing with data falls into one of two buckets.

- Manual processes and work performed by people who do not need high levels of technical skill and, as such, cost less than $15.00 per hour.

- Automation processes that are set up and developed by individuals with high levels of technical ability, such as programming and platform knowledge, who cost more than $30.00 per hour.

There are pros and cons to both approaches. In this article, I outline a framework that will help you make the best business decision about how to approach data exchange.

Automation Bias

It’s been my experience that most companies default to the philosophy that data integrations and sharing should be automated. Possibly, that’s due to engineers and I.T. employees always leaning that direction, or to the notion that sharing data that isn’t automated can create scaling problems.

Their thought process leads to questions and conclusions.

- “Why in the world would you email an Excel file to your trading partners?”

- “We’re going to receive orders via an email and then someone is going to copy and paste them into our order management system?”

- “Do you want to do things like that every day?”

- “We need to write some code and make that all seamless.”

- “We need to make it real time.”

It’s not a bad line of thinking, but it can be dangerous and costly.

The perceived benefit of data automation is its ability to remove the human factor once the work is done. The disadvantage is that automation is expensive to set up and the human factor still exists in many cases.

Here’s an example.

Last week, one of the customers of my company broke our platform, which powers data integrations to retailers. The customer uploaded some new product data that it was copying for a particular retailer and put a “[“ character in the SKU field. Ultimately, that caused problems with Apache web server — the one that powers almost 50 percent of the Internet.

Over the years, we’ve built a lot of technologies and written lots of code to provide flexibility with an automated data exchange. In this particular case, however, it wasn’t anything we had done that caused the issue.

Automation is great once it’s set up, but when computers are talking to each other, the communication has to be perfect, always. If not, it requires a decent amount of expensive work to figure out why — and you may even have to start over. The maintenance component of automated data is typically massively under considered.

Data Exchange Options

Smart companies approach the question of how to handle data in a more nuanced fashion and typically think through three options.

- Fully manual. This involves people doing the work: copying and pasting data, filling out spreadsheets, and using third-party portals. Costs are calculated and planned based on throwing people at the problem. Don’t discount how far you can get with this.

- Ad hoc integrations. At this point, you’re adding I.T. resources to build and maintain data integrations. You need to share data, look at your trading partner, and then create a more automated way to integrate. Each trading partner is handled new, and most of what you do doesn’t carry over from one to the next. Costs are driven by the number of integrations and by maintenance.

- Platform. The big change here is that you still need I.T. resources but decide to buy specific tools to make things more repeatable and maintenance less costly. You still have I.T. resources, but the costs should be driven less directly by the number of integrations, and you’re adding in the costs for the technology.

The answer to a company’s requirements to handle data exchange may be just one of these options. More likely, however, it will use all three, depending on various factors.

Prioritize Data Automation

Understanding how to prioritize just when and where it makes sense to invest in automation is the key to determining your strategy.

- Trading partner. Each trading partner can have limitations with its own systems or processes. Sometimes, those determine automation need (e.g., they can only accept orders via web API) or they lean toward the use of manual processes (e.g., they have infinite made-to-order inventory, so inventory updates are really not an issue).

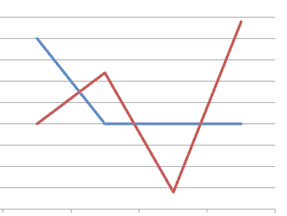

- Data type. The type of data determines a major piece of what you can automate. Product catalog leans strongly to manual while inventory favors automation. Orders and fulfillment could be either. For more, see the articles I referred to above on product catalog data, inventory visibility, orders, fulfillment.

- Financial investment. Don’t be in a hurry to invest in automation until you are making money. Automation is expensive — more so than doing things manually — so the investment needs to be justified.

Still Predicting the Future

My final thought on the question of automated versus manual data exchange and integrations is to remind you that, even though drop shipping changes the cost dynamics of inventory, you are still predicting the future. Retailers do not know if they will sell a given vendor’s products, and a supplier doesn’t know if a prospective dealer will sell anything.

In my company’s four-year history, we have thousands of examples of retailers that use our platform and tools to build automation and then fail to generate orders. Work and energy are abandoned, and the retailers would have been better off starting manually and then investing in automation once the business case aligned.

In short, be very careful of automation.