In an era when shoppers want free ecommerce delivery, knowing when and how to set shipping and handling fees can be a conundrum.

You’ll lose customers if the fees are too high. But if they’re too low or always free, your online shop risks not making enough profit to be successful.

So how do you strike the perfect balance? You do a little math (or at least a little estimating).

Free Shipping Offers

The first step is determining if and when you can offer free shipping without going broke.

Free shipping is one of the most popular online retail incentives. But what was once a marketing ploy has become a consumer expectation. Most enterprise retailers provide it in some form. It’s free with an Amazon Prime membership. And plenty of stores offer free shipping on every order regardless of size or value.

The first task is to review the products your store sells and decide if free shipping is suitable for any or all of them.

To begin, gather the facts about your current shipping costs. How much does it cost to ship one product and 10? Do some products cost more or require additional effort?

Here is a plan.

- Determine current shipping rates. Your ecommerce platform almost certainly does shipping rate calculations in real-time, so use it. Set up several test orders that include both product weight and package dimensions.

You can do this for all products or focus on products that are heavy, bulky, or otherwise hard to ship. Large pillows, for example, can cost significantly more to ship than most merchants expect thanks to dimensional weight charges.

Finally, remember that for relatively small and heavy items, flat-rate shipping is your friend.

- Estimate packing material expenses. The packaging materials required to send a t-shirt, for example, are simpler than for a sofa, a glass vase, or a kettlebell. If your business uses a warehouse and fulfillment service, material expenses could be included in a pick-and-pack fee or similar. If so, the math just became easier. Otherwise, estimate material costs yourself.

- Include labor costs. Customer orders won’t box themselves. You will pay a third-party fulfillment service or employees to do the work.

- Check popular product combinations. If consumers frequently purchase your kettlebells, glass vases, or t-shirts in pairs, check out those shipping rates, too. Does selling more of an item reduce the cost?

Free Shipping for Pet Rocks

Let’s work through an example. Imagine that you’ve just licensed the “pet rock” from the estate of Gary Dahl, the creator.

In the 1970s, Dahl devised a way to keep his dog amused. He took some small stones and put them in a cardboard box. His friends saw the contraption and wanted one, too. Thus the pet rock was born.

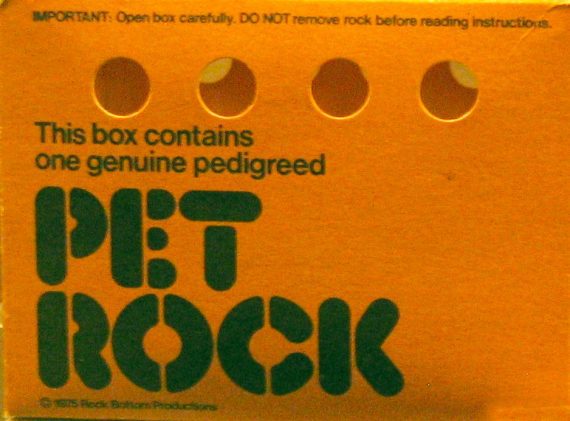

By 1975, consumers could purchase a pet rock in many stores. Dahl marketed the stones as live animals, placing them in a perforated cardboard box. I had one —my dad mumbled under his breath all the way to the checkout stand.

Gary Dahl sold his rocks like live pets. The box, shown here, included holes. Image: Wikipedia.

Dahl’s pet rocks were relatively small. But you’ve decided to market larger versions, so let’s look at the costs.

If your warehouse is in Los Gatos, California, zip code 95030, and you’re shipping a 40-pound per rock in a 12-inch, cube-shaped box to zip code 58318 in Bottineau, North Dakota (Dahl’s birthplace), the UPS would have charged $81.76 on July 15, 2022, for ground shipping.

Take that amount and add the cost of a custom, triple-reinforced pet rock box (say $7) and the cost of labor ($5 — 12 minutes at $25 per hour). Thus, shipping a large pet rock would cost $93.76.

If you sell 40-pound pet rocks for $350 with a certified pedigree, and your wholesale cost is $18, there is room to offer free shipping. The math is clear:

$350 selling price – $18 cost of goods – $93.76 shipping and handling = $238.24 gross profit

When Free Shipping Won’t Work

However, before you know it someone else starts to sell pet rocks, forcing you to reduce prices to $100 each. Now it doesn’t make sense to offer free shipping.

$100 selling price – $18 cost of goods – $93.76 shipping and handling = $11.76 gross loss

As an online merchant, you have two options. You can stop selling pet rocks and focus on other products, like the easier-to-ship pet feathers, or pass at least a portion of the shipping expense to your customers.

Now we are back to the conundrum. How much of the shipping cost should you pay? Testing can help decide. For example, Shopify merchants have several shipping rate testing apps to pick from. HulkApps makes one, as does ShipScout.

These apps allow showing different shipping rates to sets of customers and then tracking which works better. But don’t test once and be done. Create permanent shipping-charge tests to optimize conversions and profits.