I recently spoke at a conference regarding supply chain collaboration. As I was preparing my presentation, it occurred to me that ecommerce companies can greatly benefit from improving their supply chain efforts.

When considering the functionality of their supply chains, ecommerce merchants should accomplish three goals that at first seem competing, but are actually complementary:

- Reduce inventory;

- Increase selection (the number of SKUs you carry);

- Improve availability (eliminate stock-outs).

To accomplish all three, you first have to measure and track of all three data points. Remember the maxim: “What gets measured gets done.” However, there is a better rule: “What gets measured and reported gets done.” Therefore, start measuring and reporting in a dashboard for all in your company to see. This will create a cultural shift in the company, focusing on these critical factors.

The reasons these goals are so important is because today’s consumers are not willing to wait. We are living in the “now” economy. Therefore, if an item is out of stock, you are likely losing orders. You are also likely receiving order cancelations and, potentially, alienating clients. If you increase your selection you will increase your sales. But, conversely, reducing your inventory improves your cash, your return on investment, and your ability to invest in other areas of your business.

So what is a merchant to do?

Below is a short list of strategies to achieve all three goals and reap the financial rewards.

- Reduce lead-times

- Improve vendor communications

- Overcome employee inertia

Reduce lead-times

This has tremendous benefits. Reducing lead-time has the potential by itself to accomplish all three goals. How to reduce lead-time? Here is how we have accomplished this.

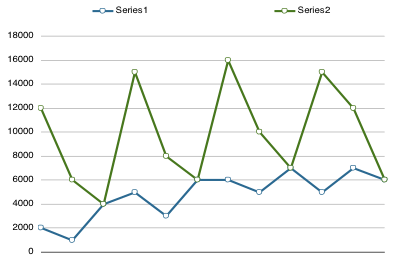

Order in regular intervals and in small batches. We chose to order once a week; it works well in our business. The graph below illustrates the difference.

This graph shows the effects of purchasing $15,000 every three weeks, versus $5,000 every week.

In the graph, the green line shows purchases of $15,000 every three weeks. The blue line shows a weekly purchase of $5,000. Weekly sales fluctuate but are the same for each of the purchasing intervals. Notice that at the end we have an equal amount of dollars in inventory (roughly $6,000), but our average inventory during the entire period is much higher with purchasing $15,000 every three weeks.

The small batches reduce inventory and increase both cash and availability. In fact, in this simplistic example, average inventory drops to less than half if you purchase weekly. Furthermore, if you order weekly versus every three weeks, you are much less likely to run out of certain items.

The only problem companies are faced with as far as increasing order frequencies is how time consuming it might be to go through a large number of SKUs and place orders weekly. For this you need to develop a good tool that will help inventory buyers go through many SKUs quickly. To do this, we use our own demand-planning spreadsheet.

With this tool, all data is available in one place, which allows our buyers to make quick decisions. They can now go through 2,000 to 3,000 SKUs in roughly two hours. Also, this spreadsheet uses formulas that specify only those items that need ordering. These formulas analyze many more factors than what a human could consider without the help of a computer. This makes the process faster and more accurate.

Improve vendor communications

Monitor your vendors and work with them to create consistency in delivery times. This is especially significant if you have a product that is manufactured for you. Remember, you are not only concerned with the speed, but, also, in the consistency of the lead-time. This is important since it allows you to plan.

Develop a culture of open communications with your vendors. Many people dealing in supply chains look at the statistics and the numbers from each vendor. But remember, vendors are people, and communications between people is a key to success.

You should always work to create a better relationship with your vendors. This means to call them from time to time and, if possible meet with them. Ecommerce merchants should strive to provide vendors with unique experiences, much like we do customers. This will put your company at the top of their list when introducing new items, or when product availability on their end is a problem.

It is also important to create a system that encourages collaboration. Our supply chain system allows for communication on an order level, an order line-item level, and a shipment level. It is open for all to see — to everyone in the company. This improves communications internally and externally with our suppliers and customers.

We also created an innovative approach called “early order,” which is simple but very powerful. We create orders for a 90-day usage of product. Our vendors then place the items in a “ready to ship” status. We then pull what we need weekly. This has created amazing efficiencies. We have reduced our lead-time from 60 days to one week! It summarizes all of the benefits discussed in this article.

Overcome employee inertia

Last but not least is the need to overcome employee inertia. As you are implementing some or all of these strategies, you might notice — as we did — that not everything is going as planned.

For example, we implemented them and noticed that we were accomplishing two out of the three goals: We were increasing SKU selection and we were improving availability, but inventory kept increasing!

We looked at our processes and could not understand why it was happening. We decided to speak with our oil painting buyer, to see how she was using the tools and placing the orders. She stated that she doesn’t have confidence in our system nor does she trust the vendors to deliver on time.

Therefore, she was buffering her orders by adding more units to every SKU. Once we understood this, we worked to make some changes in our algorithm and explained the system and the process to the buyer. This helped her trust the system and use its actual recommendations. Subsequently inventory started dropping and all three goals were being achieved.

Overall, the total impact on my ecommerce business from this process has been (a) a material increase of sales, (b) a major and ongoing reduction of inventory, (c) a better availability of cash, and (d) higher net income.

This process is not complex. But it does take work to accomplish. It starts with the understanding that you can accomplish all three goals — reduce inventory, increase selection, and improve availability — at the same time

Please post your questions and comments, below.